WASHINGTON — The National Transportation Safety Board (NTSB) on Tuesday released its preliminary report into the depressurization incident last month that forced an Alaska Airlines flight to make an emergency return to Portland International Airport (PDX) shortly after taking off.

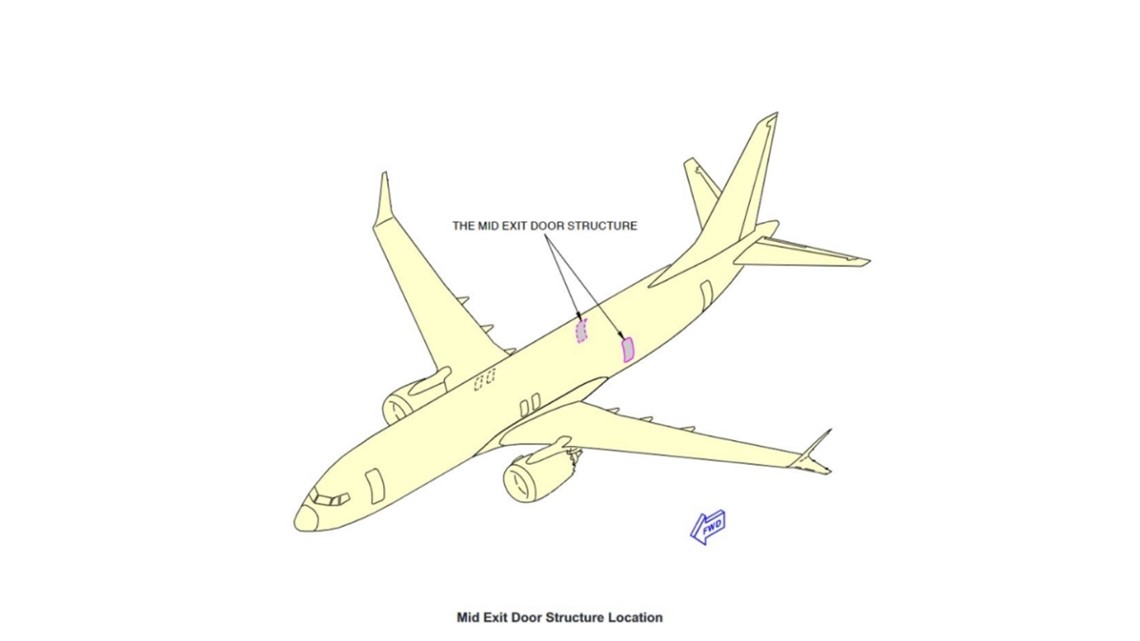

The incident was caused by a panel called a Mid Exit Door (MED) plug that abruptly blew out from the side of the Boeing 737 MAX 9 twinjet at 15,000 feet. The preliminary report states that a key set of four anchoring bolts were likely missing at the time of the accident, and the error appears to have occurred when the plane was in Boeing's Renton, Washington manufacturing facility last summer.

The MED plug attaches with two slots at the top, two hinges at the bottom and 12 "stop fittings" that prevent the panel from moving outward from the rest of the plane. Each slot and hinge is secured by an anchor bolt that prevents the door from moving vertically, and previous NTSB updates suggested that the plug appeared to have slid upward before popping out.

According to the report, the investigators found damage on the 12 stop fittings that fit the pattern of the door first sliding up and then popping out, but crucially, the bore holes where the four bolts would have been slotted showed no sign of the kind of damage that would have been caused if the bolts had been present when the door detached.

"Overall, the observed damage patterns and absence of contact damage or deformation around holes associated with the vertical movement arrestor bolts... indicate that the four bolts that prevent upward movement of the MED plug were missing before the MED plug moved upward off the stop pads," the NTSB wrote.

The depressurization incident

The aircraft was almost brand new; it was delivered to Alaska in late October and put into service in November. It had accumulated 510 hours of flight time and completed 154 pressurization cycles (one pressurization cycle normally happens during one takeoff and landing, the equivalent of one flight) at the time of the accident, according to the NTSB report.

The plane departed PDX for Ontario, California on Jan. 5, operating as Alaska Airlines Flight 1282, and took off at 5:06 p.m., according to the NTSB report. The door plug blew out about six minutes later, while the plane was still climbing above the Portland metro area. The overhead oxygen masks deployed for the passengers and the pilots quickly descended below 10,000 feet, then returned to PDX for an emergency landing.

The flight data recorder shows an abrupt drop in cabin pressure at 5:12 p.m. and 33 seconds, when the airplane was at about 14,830 feet, according to the NTSB report, with the pressure differential between the inside and outside of the plane falling from 5.7 psi to 0 in just a few seconds. The aircraft had reached a maximum height of 16,320 feet when the pilots began to descend, a little over one minute after the depressurization began.

Fortunately, no one was sitting in the seat closest to the door plug, but a teenager in the next seat over lost his shirt when it was pulled off him and through the opening. Several passengers' cell phones were found in the Cedar Mill area north of Beaverton in the following days, and a Portland science teacher eventually found the missing door plug in his backyard.

The incident prompted the Federal Aviation Administration (FAA) to ground all 737 MAX 9 planes nationwide. Alaska and United Airlines are the only two U.S. carriers whose fleets include the MAX 9.

The planes began returning to service on Jan. 26 after the FAA approved an inspection process to confirm the integrity of the door plugs, but the incident has sparked widespread criticism and scrutiny of Boeing in general and the 737 MAX product line in particular, especially coming just a few years after two crashes involving 737 MAX 8 jets that killed 346 people. The company is also now facing a class-action lawsuit from passengers on the Alaska flight.

What is a door plug?

Door plugs are installed on certain planes to permanently seal off unused emergency exits. The legally required number of emergency exits depends on the total number of seats on a plane, so each MAX-9 fuselage is built with an extra pair between the wings and rear doors in case a carrier opts for maximum seating.

Alaska and United don't put in enough seats to require the extra exits, so they seal them off by bolting door plugs into the openings. Carriers typically opt for door plugs because they're lighter than a fully functional emergency door and simpler to maintain, according to the NTSB report. They also can include a full window instead of a small porthole, so from the inside they look just like any other part of the cabin wall.

Manufacturing history

Boeing 737 MAX 9 fuselages — the central cabin shell without the wings — are manufactured by a contractor called Spirit AeroSystems and then shipped to Boeing, which manufactures the rest of the plane.

The specific door plug involved in the accident was manufactured at a Spirit AeroSystems factory in Malysia in March, and shipped to another Spirit facility in Wichita, Kansas in May, where it was installed in a 737 MAX 9 fuselage. The fuselage was shipped out to Boeing by rail on Aug. 20 and arrived at the Renton factory 11 days later, according to the NTSB report.

Boeing's first step is to check the fuselages for manufacturing defects, and a Sept 1. Boeing report noted that the company had found five damaged rivets near the edge of the door plug, according to the NTSB report. The four vertical movement bolts had to be removed in order to swing the door plug outward on its lower hinges to make room to fix the rivets. Spirit Aerosystems personnel on site completed the work on Sept. 19.

A text message between two Boeing team members at around 6:40 p.m. on Sept. 19 shows a picture of the door plug back in place, but three of the bolt slots are visible and do not appear to have bolts in them, according to the NTSB report. The Boeing staff were discussing the process of restoring the internal cabin wall covering for the door, which had not yet been done.

The plane was delivered to Alaska Airlines on Oct. 31 and entered service on Nov. 11, according to the report, but it was taken out of service again from Nov. 27 to Dec. 7 for installation of an antenna for onboard Wi-Fi service at a facility in Oklahoma City operated by another contractor called AAR. That company's officials told the NTSB that they have retrofitted about 60 Alaska Airlines 737 planes and the process does not involve opening the door plug.

"The manufacturing/human performance group has done a complete records review from the time the event airplane left the Boeing factory to the time of the accident and found no evidence that the left MED plug was opened after leaving Boeing's facility," the NTSB wrote.

The NTSB cautioned that Tuesday's report is preliminary and the investigation is still ongoing.